Rigid Flex Circuits Be Used in Wearable Technology

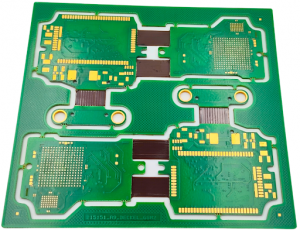

Rigid-flex circuits combine rigid and flexible sections of dielectric material to create a single, integrated PCB. They’re often utilized in medical devices and wearables that require a high-density layout and flexibility for dynamic adaptability. Rigid-flex circuits offer a variety of benefits including improved device stability, 3-dimensional freedom of design, reduced interconnection components and wires, and significant space savings.

The hybrid nature of rigid-flex circuits allows them to function reliably in a range of vibration environments. This helps to reduce the risk of fatigue, cracking, or failure in high-shock and vibration conditions that may be experienced by the device during operation. Additionally, the hybrid nature of rigid-flex PCBs allows for greater component density and a reduction in overall product weight compared to traditional rigid boards and cables.

For example, rigid-flex PCBs can be used in wearable technology like smartwatches, fitness trackers, and augmented reality (AR) glasses to monitor patient health. These types of devices must be able to flex and adapt to the body’s movements, allowing them to provide accurate results and remain stable throughout use. The rigid-flex technology in these devices offers superior durability and reliability, making them the ideal choice for medical applications that must withstand physical stress and movement.

When it comes to designing rigid-flex circuits, you’ll need to work with an experienced engineering and PCB manufacturing company that has the knowledge and expertise required to help you bring your vision to life. This includes understanding your project’s goals and helping you to find the best solutions for its challenges. Ultimately, this can make the difference between success and failure for your product.

Can Rigid Flex Circuits Be Used in Wearable Technology?

Working with a PCB manufacturing company that has experience creating rigid-flex boards will also save you time and money in the long run. This is because they can provide you with a single, integrated circuit board that eliminates the need for multiple rigid flex circuits and connector cables to be connected together. This streamlines the production process and decreases the likelihood of errors that would otherwise require costly rework.

A good PCB manufacturing company will also ensure that your rigid-flex circuits are properly constructed, minimizing the chance of defects or failure. They’ll begin by reviewing your design and identifying any potential issues before the fabrication process begins. They’ll then apply a thorough testing regime to ensure the integrity of your rigid-flex circuit board. This will include testing for continuity, resistance, and electrical conductivity.

To get started with your rigid-flex PCB project, contact the professionals at Hemeixin Electronics today to discuss your needs and request a quote!

The hybrid construction of rigid-flex circuits makes them an excellent choice for many different types of electronics. In addition to providing enhanced durability and reliability, they also offer several other advantages, like the ability to bend and adapt to the user’s movements, enabling them to stay securely in place on the body. Whether you’re looking for a new PCB design or want to optimize the performance of your existing one, rigid-flex circuits are an excellent option for any application.